Eames Kiosk from the 1964 NY World’s Fair: A Collaboration and Case for its Missing Finials

In 1961 Charles and Ray Eames began working with Eero Saarinen on concepts for IBM’s pavilion at the 1964 New York World’s Fair. While the final design—a vast ovoid structure containing a multi-screen experience perched on tree-like supports—was distinct architecturally and theatrically, the experience for visitors sauntering through the pavilion at ground level was intended to be free-flowing and experiential. The result incorporated elements that the Eames Office had created for their Mathematica exhibits in Los Angeles and Chicago, plus new presentations and hands-on elements, all spread out beneath colorful purpose-built kiosks whose design leaned more toward a carnival or bandstand aesthetic—a perfect foil for the advanced technologies being premiered in the pavilion.

In 2013, The Henry Ford acquired one of the kiosks that was originally installed in the IBM Pavilion at the 1964 New York World’s Fair. You can learn more about the kiosk’s installation and construction here:

- https://www.thehenryford.org/explore/blog/welcome-eames-kiosk

- https://www.thehenryford.org/explore/blog/video-building-the-eames-kiosk

The Henry Ford’s kiosk has been on exhibit since 2014—that is, except for a subtle but ultimately glaring omission: it was missing the two elaborately turned decorative finials that were positioned at the peak of its roof. Luckily the one other surviving kiosk—in the Vitra Design Museum’s collections—had retained its finials. Vitra generously provided measurements and photographs of their kiosk’s finials, enabling us to fabricate replacements—via a collaborative effort between 3D printing technology company Desktop Metal, Inc. and conservation staff at The Henry Ford.

Left image: The kiosk at The Henry Ford. Right image: The two finials are present during the 1964 New York World’s Fair.

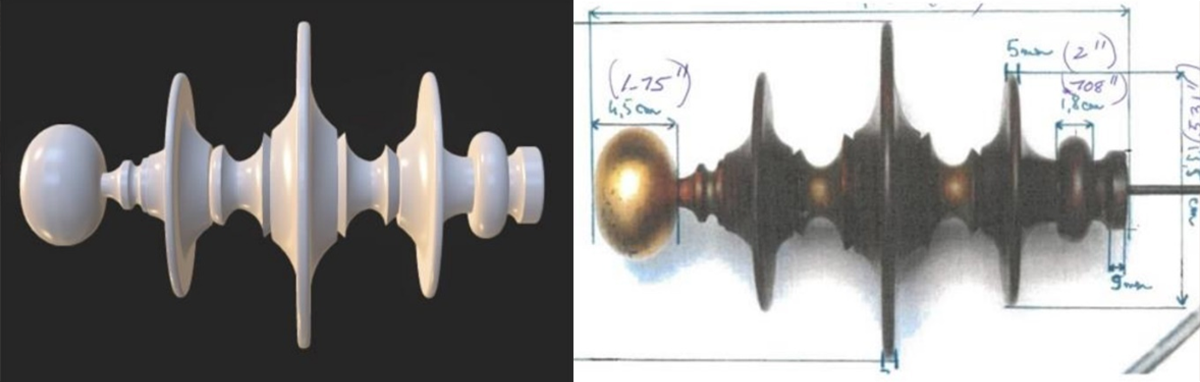

To re-create the two finials, binder jet manufacturing was selected as the method of fabrication. The finials were modeled by conservator Cuong Nguyen using a CAD program and measurements taken from an image of one of Vitra Design Museum’s finials.

Left image: CAD model of the finial. Right image: Reference photograph of the finial.

Forust, a subsidiary of Desktop Metal, Inc. provided the philanthropic support and technology to implement a sustainable 3D additive manufacturing approach using a high-speed single-pass printer engine and recycled sawdust held in a bio-epoxy resin print medium. This technology was featured on an episode of The Henry Ford’s Innovation Nation with Mo Rocca.

The left image shows a bed of sawdust that covers printed components of the finials that can be seen uncovered in the right image. Images from Desktop Metal, Inc.

Photographs of the printed finials after the application of a stain. The images were provided by Desktop Metal, Inc.

The parts provided by Desktop Metal, Inc were then re-toned to match the existing wood surfaces and gilded with 23.4K gold leaf. A dowel was inserted at the base as a fastener.

The surface finish of the printed parts was compared and matched to the original finish on the kiosk. The above images show several types of gold finishes.

The finished pair of finials before the installation on the kiosk.

Above Images: The kiosk was complete with two fabricated finials.

Special thanks to Desktop Metal, Inc. (Kristal Kilgore, Soniya Patel, Benjamin Leone, Sarah Webster)

Cuong T. Nguyen is senior conservator (objects & functional artifacts) at The Henry Ford.